-

EU New Battery Regulation: How It Drives Demand for Precision CNC Machining of Battery TraysThe EU's new Battery Regulation (Regulation (EU) 2023/1542) has officially come into force, marking a paradigm shift in the global battery and automotive industries. For manufacturers of battery trays-critical components for electric vehicles (EVs), energy storage systems, and industrial equipmen2025-12-09Read More >>

EU New Battery Regulation: How It Drives Demand for Precision CNC Machining of Battery TraysThe EU's new Battery Regulation (Regulation (EU) 2023/1542) has officially come into force, marking a paradigm shift in the global battery and automotive industries. For manufacturers of battery trays-critical components for electric vehicles (EVs), energy storage systems, and industrial equipmen2025-12-09Read More >> -

Complete Guide to Custom CNC Bike Parts ManufacturingCustom CNC (Computer Numerical Control) bike parts manufacturing is a precision-driven subtractive process that transforms raw materials into high-performance, tailored components-redefining bike fit, durability, and performance for enthusiasts, professional riders, and OEMs alike. This guide cover2025-11-08Read More >>

Complete Guide to Custom CNC Bike Parts ManufacturingCustom CNC (Computer Numerical Control) bike parts manufacturing is a precision-driven subtractive process that transforms raw materials into high-performance, tailored components-redefining bike fit, durability, and performance for enthusiasts, professional riders, and OEMs alike. This guide cover2025-11-08Read More >> -

How to Choose a CNC Small Batch Prototype Machining Factory in China?Selecting a CNC small batch prototype machining factory in China requires a strategic blend of technical evaluation, quality assurance, and practical considerations. Below is a refined guide incorporating the latest industry trends and actionable insights, leveraging recent advancements in smart man2025-09-26Read More >>

How to Choose a CNC Small Batch Prototype Machining Factory in China?Selecting a CNC small batch prototype machining factory in China requires a strategic blend of technical evaluation, quality assurance, and practical considerations. Below is a refined guide incorporating the latest industry trends and actionable insights, leveraging recent advancements in smart man2025-09-26Read More >> -

6061 vs 6082 Aluminum: A Comprehensive Comparison GuideAluminum alloys 6061 and 6082 both belong to the 6000-series (aluminum-magnesium-silicon alloys), a category valued for its balance of strength, formability, and cost-effectiveness. However, their distinct chemical compositions and performance traits make them suited for vastly different application2025-09-24Read More >>

6061 vs 6082 Aluminum: A Comprehensive Comparison GuideAluminum alloys 6061 and 6082 both belong to the 6000-series (aluminum-magnesium-silicon alloys), a category valued for its balance of strength, formability, and cost-effectiveness. However, their distinct chemical compositions and performance traits make them suited for vastly different application2025-09-24Read More >> -

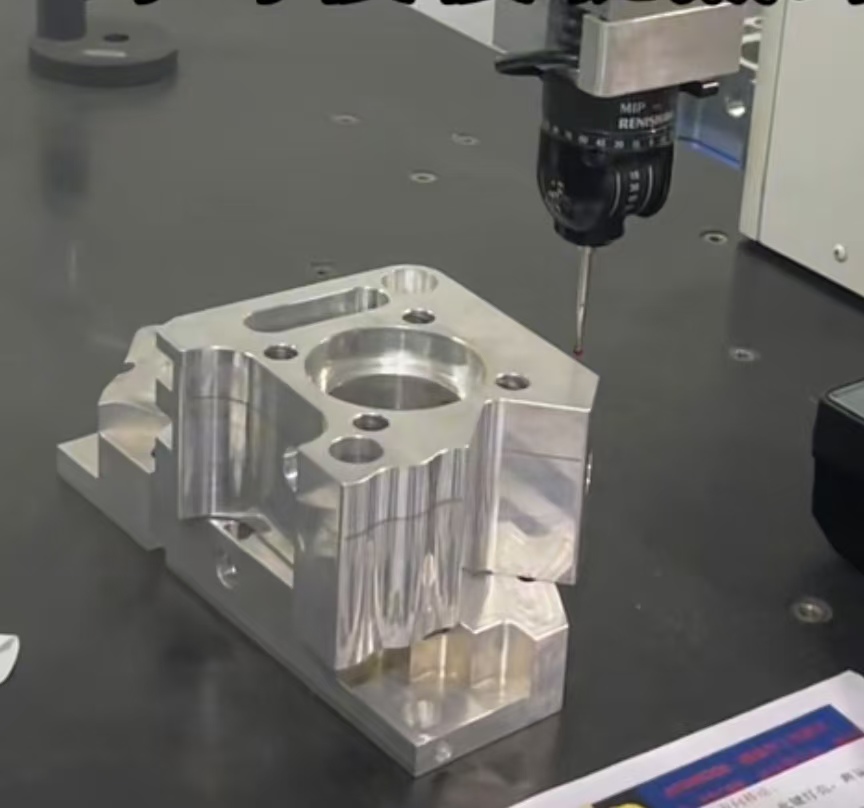

What is CMM For CNC Machining And How Does it Work? (coordinate measuring machine)What is a CMM for CNC Machining? A Coordinate Measuring Machine (CMM) is a high-precision device used to measure the geometric dimensions and tolerances of CNC-machined parts, ensuring they match the design specifications (e.g., size, shape, position of features). How Does a CMM Work? Fi2025-09-16Read More >>

What is CMM For CNC Machining And How Does it Work? (coordinate measuring machine)What is a CMM for CNC Machining? A Coordinate Measuring Machine (CMM) is a high-precision device used to measure the geometric dimensions and tolerances of CNC-machined parts, ensuring they match the design specifications (e.g., size, shape, position of features). How Does a CMM Work? Fi2025-09-16Read More >>

Reliable One Stop Supplier Of Custom Industrial Components & Assemblies