CNC Machine Services: A Key to Precision and Accuracy in Medical Device Production

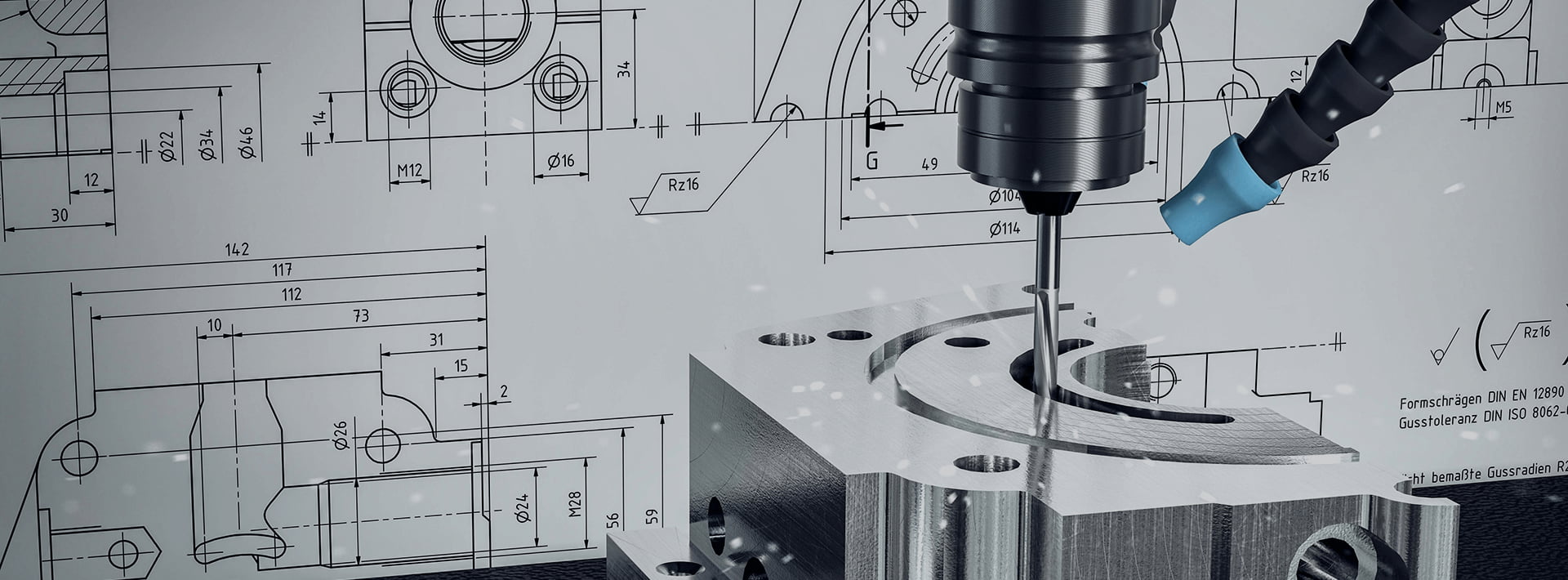

CNC (Computer Numerical Control) machine services are indeed fundamental to achieving the extreme precision, accuracy, and consistency required in modern medical device production. Here's why they are such a critical component:

First. Unmatched Precision & Tight Tolerances:

Medical devices (implants, surgical instruments, diagnostic components) often demand micron-level accuracy. CNC machining, guided by digital CAD/CAM programs, consistently achieves tolerances as tight as ��0.0005 inches (��0.0127 mm) or less.

This precision is non-negotiable for components like orthopedic implants (hips, knees, spinal devices), dental components, heart valve parts, and micro-surgical tools, where perfect fit and function are critical for patient safety and efficacy.

Second. Exceptional Repeatability & Consistency:

Second. Exceptional Repeatability & Consistency:

Once a CNC program is optimized and validated, it can produce thousands of identical parts with negligible variation.

This is paramount for mass production of medical devices, ensuring every single unit meets the exact same stringent specifications and quality standards required for regulatory approval (FDA, CE Mark, ISO 13485).

Third. Complex Geometries & Intricate Features:

Modern medical devices often feature highly complex 3D shapes, intricate internal channels (for fluidics or optics), micro-features, and contoured surfaces that are difficult or impossible to produce consistently with other methods.

Multi-axis CNC machining (5-axis, even 7-axis) allows for the creation of these complex geometries in a single setup, maintaining accuracy and reducing the risk of errors from multiple handling steps.

Fourth. Material Versatility:

Medical devices utilize a wide range of biocompatible and often challenging materials:

Metals: Titanium (Ti6Al4V), Stainless Steels (316L, 17-4PH), Cobalt-Chromium alloys, Nitinol (shape memory alloy).

Plastics: PEEK, Ultem (PEI), PTFE, Delrin, Polycarbonate, medical-grade ABS.

Ceramics: Zirconia, Alumina.

CNC machining can effectively handle all these materials, producing smooth surface finishes and precise features essential for biocompatibility and performance.

Fifth. Superior Surface Finishes:

Many medical components require exceptionally smooth surfaces to minimize friction, prevent bacterial adhesion, ensure biocompatibility, or facilitate cleaning/sterilization.

CNC machining can achieve very fine surface finishes directly off the machine, and processes like CNC polishing can further enhance this critical characteristic.

Sixth. Scalability and Flexibility:

Prototyping & R&D:CNC is ideal for rapid prototyping of complex medical device concepts, allowing for quick design iteration and functional testing using final materials.

Low-Volume Production: Perfect for specialized instruments, custom implants (patient-specific), or pilot production runs.

High-Volume Production: Automated CNC cells enable efficient, lights-out manufacturing for high-volume disposable devices or components.

Seventh. Regulatory Compliance & Validation:

Reputable CNC machine shops serving the medical industry operate under strict Quality Management Systems (QMS) like ISO 13485 and are familiar with FDA regulations (21 CFR Part 820).

They provide comprehensive documentation (material certifications, inspection reports, process validations, full traceability) essential for regulatory submissions and audits.

Key Applications in Medical Devices:

Orthopedic Implants: Knee, hip, shoulder, spinal components (precise bearing surfaces, porous structures).

Surgical Instruments: Scalpel handles, forceps, clamps, retractors, endoscopic tools, drill guides (complex shapes, sharp edges).

Dental Implants & Restorations:Abutments, crowns, bridges, surgical guides.

Cardiovascular Devices: Heart valve components, pacemaker housings, stent deployment tools.

Diagnostic Equipment: Housings, fluidic components, sensor mounts, optical components for imaging systems (MRI, CT, ultrasound).

Drug Delivery Devices: Insulin pen components, inhaler mechanisms, micro-pump parts.

Endoscopes & Laparoscopes: Precision shafts, lens housings, articulation components.

Choosing the Right CNC Service Partner for Medical Devices:

Medical Industry Experience & Certifications: ISO 13485 certification is essential. Look for proven experience with similar devices and materials.

Advanced Capabilities: Multi-axis machining, micro-machining, Swiss turning, EDM (for specific applications).

Stringent Quality Control: In-process inspection, CMM (Coordinate Measuring Machine) capabilities, skilled metrologists.

Material Expertise: Knowledge of biocompatibility, material certifications, and machining characteristics.

Documentation & Traceability: Robust systems for full material and process traceability.

Cleanroom Options: For devices requiring higher levels of cleanliness during machining or assembly.

Conclusion:

CNC machine services are far more than just a manufacturing process; they are a critical enabler of modern medical device innovation and production. The unparalleled precision, repeatability, material flexibility, and ability to produce complex geometries make CNC machining indispensable for creating life-saving and life-enhancing devices that meet the rigorous demands of the healthcare industry and regulatory bodies. Partnering with a capable and certified CNC service provider is a strategic necessity for any medical device manufacturer aiming for success.

First. Unmatched Precision & Tight Tolerances:

Medical devices (implants, surgical instruments, diagnostic components) often demand micron-level accuracy. CNC machining, guided by digital CAD/CAM programs, consistently achieves tolerances as tight as ��0.0005 inches (��0.0127 mm) or less.

This precision is non-negotiable for components like orthopedic implants (hips, knees, spinal devices), dental components, heart valve parts, and micro-surgical tools, where perfect fit and function are critical for patient safety and efficacy.

Once a CNC program is optimized and validated, it can produce thousands of identical parts with negligible variation.

This is paramount for mass production of medical devices, ensuring every single unit meets the exact same stringent specifications and quality standards required for regulatory approval (FDA, CE Mark, ISO 13485).

Third. Complex Geometries & Intricate Features:

Modern medical devices often feature highly complex 3D shapes, intricate internal channels (for fluidics or optics), micro-features, and contoured surfaces that are difficult or impossible to produce consistently with other methods.

Multi-axis CNC machining (5-axis, even 7-axis) allows for the creation of these complex geometries in a single setup, maintaining accuracy and reducing the risk of errors from multiple handling steps.

Fourth. Material Versatility:

Medical devices utilize a wide range of biocompatible and often challenging materials:

Metals: Titanium (Ti6Al4V), Stainless Steels (316L, 17-4PH), Cobalt-Chromium alloys, Nitinol (shape memory alloy).

Plastics: PEEK, Ultem (PEI), PTFE, Delrin, Polycarbonate, medical-grade ABS.

Ceramics: Zirconia, Alumina.

CNC machining can effectively handle all these materials, producing smooth surface finishes and precise features essential for biocompatibility and performance.

Fifth. Superior Surface Finishes:

Many medical components require exceptionally smooth surfaces to minimize friction, prevent bacterial adhesion, ensure biocompatibility, or facilitate cleaning/sterilization.

CNC machining can achieve very fine surface finishes directly off the machine, and processes like CNC polishing can further enhance this critical characteristic.

Sixth. Scalability and Flexibility:

Prototyping & R&D:CNC is ideal for rapid prototyping of complex medical device concepts, allowing for quick design iteration and functional testing using final materials.

Low-Volume Production: Perfect for specialized instruments, custom implants (patient-specific), or pilot production runs.

High-Volume Production: Automated CNC cells enable efficient, lights-out manufacturing for high-volume disposable devices or components.

Seventh. Regulatory Compliance & Validation:

Reputable CNC machine shops serving the medical industry operate under strict Quality Management Systems (QMS) like ISO 13485 and are familiar with FDA regulations (21 CFR Part 820).

They provide comprehensive documentation (material certifications, inspection reports, process validations, full traceability) essential for regulatory submissions and audits.

Key Applications in Medical Devices:

Orthopedic Implants: Knee, hip, shoulder, spinal components (precise bearing surfaces, porous structures).

Surgical Instruments: Scalpel handles, forceps, clamps, retractors, endoscopic tools, drill guides (complex shapes, sharp edges).

Dental Implants & Restorations:Abutments, crowns, bridges, surgical guides.

Cardiovascular Devices: Heart valve components, pacemaker housings, stent deployment tools.

Diagnostic Equipment: Housings, fluidic components, sensor mounts, optical components for imaging systems (MRI, CT, ultrasound).

Drug Delivery Devices: Insulin pen components, inhaler mechanisms, micro-pump parts.

Endoscopes & Laparoscopes: Precision shafts, lens housings, articulation components.

Choosing the Right CNC Service Partner for Medical Devices:

Medical Industry Experience & Certifications: ISO 13485 certification is essential. Look for proven experience with similar devices and materials.

Advanced Capabilities: Multi-axis machining, micro-machining, Swiss turning, EDM (for specific applications).

Stringent Quality Control: In-process inspection, CMM (Coordinate Measuring Machine) capabilities, skilled metrologists.

Material Expertise: Knowledge of biocompatibility, material certifications, and machining characteristics.

Documentation & Traceability: Robust systems for full material and process traceability.

Cleanroom Options: For devices requiring higher levels of cleanliness during machining or assembly.

Conclusion:

CNC machine services are far more than just a manufacturing process; they are a critical enabler of modern medical device innovation and production. The unparalleled precision, repeatability, material flexibility, and ability to produce complex geometries make CNC machining indispensable for creating life-saving and life-enhancing devices that meet the rigorous demands of the healthcare industry and regulatory bodies. Partnering with a capable and certified CNC service provider is a strategic necessity for any medical device manufacturer aiming for success.