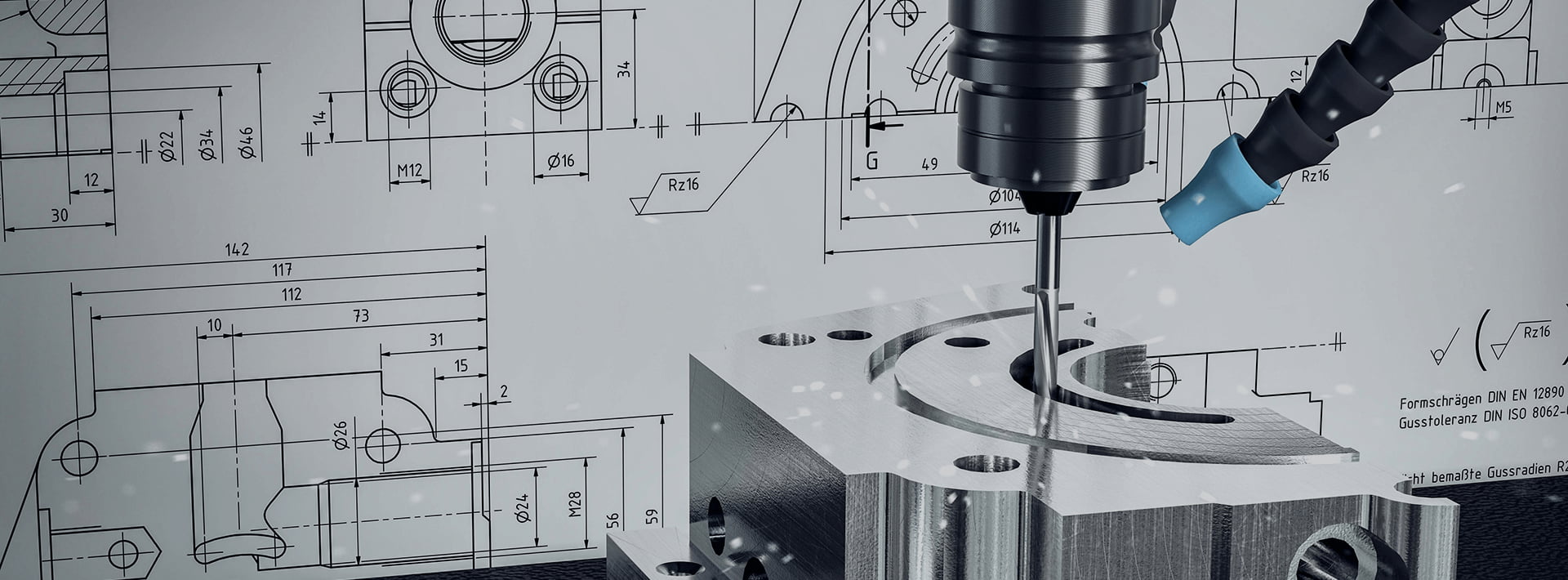

CNC Milling Services: Produce CNC Lathe Machine Parts

Here's a comprehensive overview of CNC milling services for producing CNC lathe machine parts, covering key aspects for successful manufacturing:

. Why CNC Milling for Lathe Parts?

- Complex Geometries: Milling creates slots, holes, flats, and intricate features impossible on a lathe.

- Multi-Axis Capability: 5-axis milling handles angled surfaces and compound curves (e.g; turret faces, tool holders).

- Material Versatility: Machines hardened steels, cast iron, aluminum, and engineering plastics used in lathe construction.

- Precision: Achieves tight tolerances (+/-0.01-0.05 mm) critical for spindle housings, beds, and carriages.

. Critical Lathe Components Produced via Milling

- Headstock Body: Housing for spindles bearings (requires bore accuracy).

- Cross-Slides & Carriages: Complex sliding parts with dovetails T-slots.

- Tool Turrets: Indexing mechanisms with precision mounting holes.

- Tailstock Bodies: Clamping bores and quill guides.

- Brackets Plates: Motor mounts, chip guard frames, control panels.

- Gearbox Housings: Enclosures with bearing seats and oil galleries.

. Technical Requirements

- Tolerances: +/-0.02 mm for bearing seats, +/-0.05 mm for structural fits.

- Surface Finishes:

- 0.8-1.6 m Ra for sliding surfaces (e.g., ways).

- 3.2 m Ra for non-critical faces.

- Post-Processing:

- Stress relieving (for large beds).

- Hardening tempering (gears, shafts).

- Grinding for critical flatness parallelism.

. Manufacturing Considerations

- Fixturing: Custom jigs to secure irregular parts (e.g., lathe beds).

- Tooling: Carbide end mills for hardened steel; diamond-cut for aluminum.

- Quality Control: CMM inspection for GD&T, bore gauges, surface testers.

- Volume Flexibility: Prototypes (1-10 units) to production runs (1000+).

. Partner Selection Checklist

- Experience: Look for machine tool part specialization.

- Capabilities: 4/5-axis mills, large bed capacity (for lathe beds).

- Certifications: ISO 9001, AS9100 (if aerospace adjacent).

- Testing Reports: Request material certs (MTRs) and first-article inspection.

. Cost Optimization Tips

- Design: Avoid deep pockets (<4 X tool diameter); standardize hole sizes.

- Material: Use free-cutting steels (12L14) where possible.

- Batching: Combine multiple parts in single setups.

. File Requirements

Provide suppliers with:

- 3D Models: STEP, IGES, or Parasolid formats.

- 2D Drawings: Critical dimensions, tolerances, surface callouts.

- Assembly Context: Clarify interfacing parts functions.

Pro Tip: For legacy machines, offer a sample part for reverse engineering if drawings are unavailable. Many shops offer scanning remodeling services.

Recommended Suppliers (by Region)

- North America: Protolabs, Xometry, Fathom Manufacturing

- EU: Hubs, KAMPF, Schunk Group

- Asia: Star Rapid, JTR Machine (China)

By focusing on precision, material integrity, and geometric accuracy, CNC milling ensures reliable, long-lasting components for CNC lathes. Always request DFM feedback early to avoid redesign delays.

. Why CNC Milling for Lathe Parts?

- Complex Geometries: Milling creates slots, holes, flats, and intricate features impossible on a lathe.

- Multi-Axis Capability: 5-axis milling handles angled surfaces and compound curves (e.g; turret faces, tool holders).

- Material Versatility: Machines hardened steels, cast iron, aluminum, and engineering plastics used in lathe construction.

- Precision: Achieves tight tolerances (+/-0.01-0.05 mm) critical for spindle housings, beds, and carriages.

. Critical Lathe Components Produced via Milling

- Headstock Body: Housing for spindles bearings (requires bore accuracy).

- Cross-Slides & Carriages: Complex sliding parts with dovetails T-slots.

- Tool Turrets: Indexing mechanisms with precision mounting holes.

- Tailstock Bodies: Clamping bores and quill guides.

- Brackets Plates: Motor mounts, chip guard frames, control panels.

- Gearbox Housings: Enclosures with bearing seats and oil galleries.

. Technical Requirements

- Tolerances: +/-0.02 mm for bearing seats, +/-0.05 mm for structural fits.

- Surface Finishes:

- 0.8-1.6 m Ra for sliding surfaces (e.g., ways).

- 3.2 m Ra for non-critical faces.

- Post-Processing:

- Stress relieving (for large beds).

- Hardening tempering (gears, shafts).

- Grinding for critical flatness parallelism.

. Manufacturing Considerations

- Fixturing: Custom jigs to secure irregular parts (e.g., lathe beds).

- Tooling: Carbide end mills for hardened steel; diamond-cut for aluminum.

- Quality Control: CMM inspection for GD&T, bore gauges, surface testers.

- Volume Flexibility: Prototypes (1-10 units) to production runs (1000+).

. Partner Selection Checklist

- Experience: Look for machine tool part specialization.

- Capabilities: 4/5-axis mills, large bed capacity (for lathe beds).

- Certifications: ISO 9001, AS9100 (if aerospace adjacent).

- Testing Reports: Request material certs (MTRs) and first-article inspection.

. Cost Optimization Tips

- Design: Avoid deep pockets (<4 X tool diameter); standardize hole sizes.

- Material: Use free-cutting steels (12L14) where possible.

- Batching: Combine multiple parts in single setups.

. File Requirements

Provide suppliers with:

- 3D Models: STEP, IGES, or Parasolid formats.

- 2D Drawings: Critical dimensions, tolerances, surface callouts.

- Assembly Context: Clarify interfacing parts functions.

Pro Tip: For legacy machines, offer a sample part for reverse engineering if drawings are unavailable. Many shops offer scanning remodeling services.

Recommended Suppliers (by Region)

- North America: Protolabs, Xometry, Fathom Manufacturing

- EU: Hubs, KAMPF, Schunk Group

- Asia: Star Rapid, JTR Machine (China)

By focusing on precision, material integrity, and geometric accuracy, CNC milling ensures reliable, long-lasting components for CNC lathes. Always request DFM feedback early to avoid redesign delays.