How to Solve Deformation Problems in CNC Machining of Aluminium Alloys?

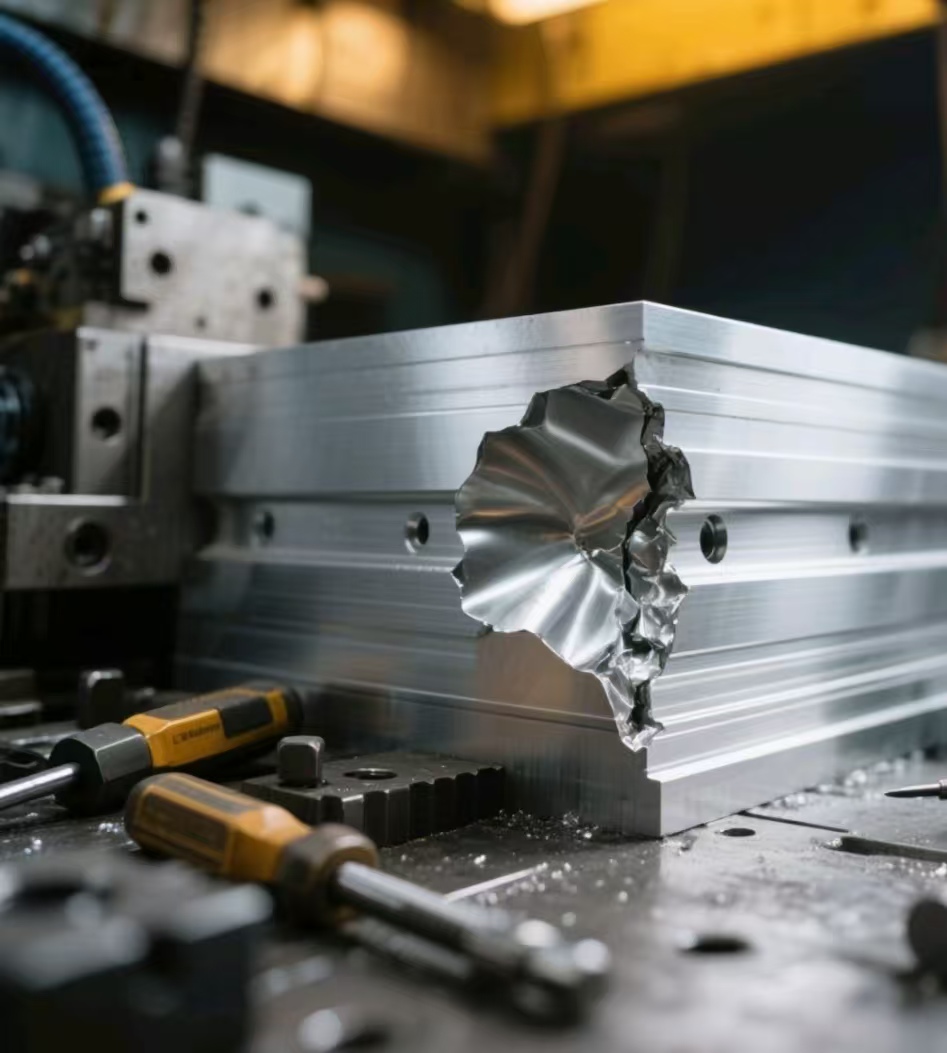

Aluminium alloys are widely used in CNC machining due to their lightweight, high strength, and excellent machinability. However, deformation during processing-such as warping, twisting, or dimensional inaccuracies-remains a common challenge, often caused by factors like residual stress, uneven material removal, and thermal expansion. Below are practical strategies to mitigate these issues:

First. Optimize Material Selection and Preparation

- Choose low-stress alloys: Prefer alloys with lower residual stress, such as 6061-T6 or 7075-T6, which undergo heat treatment to reduce internal tensions. Avoid using annealed aluminium (e.g., 1100-H14) for high-precision parts, as it is more prone to deformation.

- Stress relief before machining: Perform pre-machining heat treatment (e.g., annealing at 300-400 Celsius for 2-4 hours) to release residual stresses in the raw material. This minimizes post-machining warping caused by stress redistribution.

Second. Improve Machining Parameters

- Reduce cutting force: Use sharp tools with proper rake angles to lower cutting resistance. Opt for high-speed, low-feed machining (e.g., 1000-3000 RPM for aluminium) to minimize material deformation from excessive force.

- Control cutting depth: Avoid deep, aggressive cuts. Instead, use multiple shallow passes to distribute stress evenly and prevent localized material distortion.

Third. Enhance Workholding Techniques

- Use rigid, evenly distributed clamping: Ensure the workpiece is held firmly but not over-clamped, as excessive pressure can cause elastic deformation that rebounds after unclamping.

- Apply auxiliary supports: For thin or large parts, add supports (e.g., fixtures, jacks) to reduce vibration and bending during machining.

- Adopt vacuum or magnetic chucks: These provide uniform holding force, ideal for thin aluminium sheets that are easily deformed by traditional clamps.

Fourth. Manage Heat Generation

- Use adequate coolant: Coolant (e.g., water-soluble oils) reduces heat buildup at the cutting interface, preventing thermal expansion and warping. Direct coolant precisely at the tool-workpiece contact point.

- Avoid prolonged machining: Take breaks during long runs to let the workpiece cool, reducing accumulated thermal stress.

Fifth. Post-Machining Treatments

- Stress relief annealing: After machining, heat the part to 120-180 Celsius for 1-2 hours to release residual stresses introduced during cutting.

- Aging treatments: For heat-treatable alloys (e.g., 6061), post-machining aging can stabilize dimensions by promoting uniform precipitation of alloying elements.

By combining careful material selection, optimized machining parameters, proper workholding, and post-processing steps, deformation in CNC-machined aluminium alloys can be effectively minimized, ensuring high-precision, consistent results.