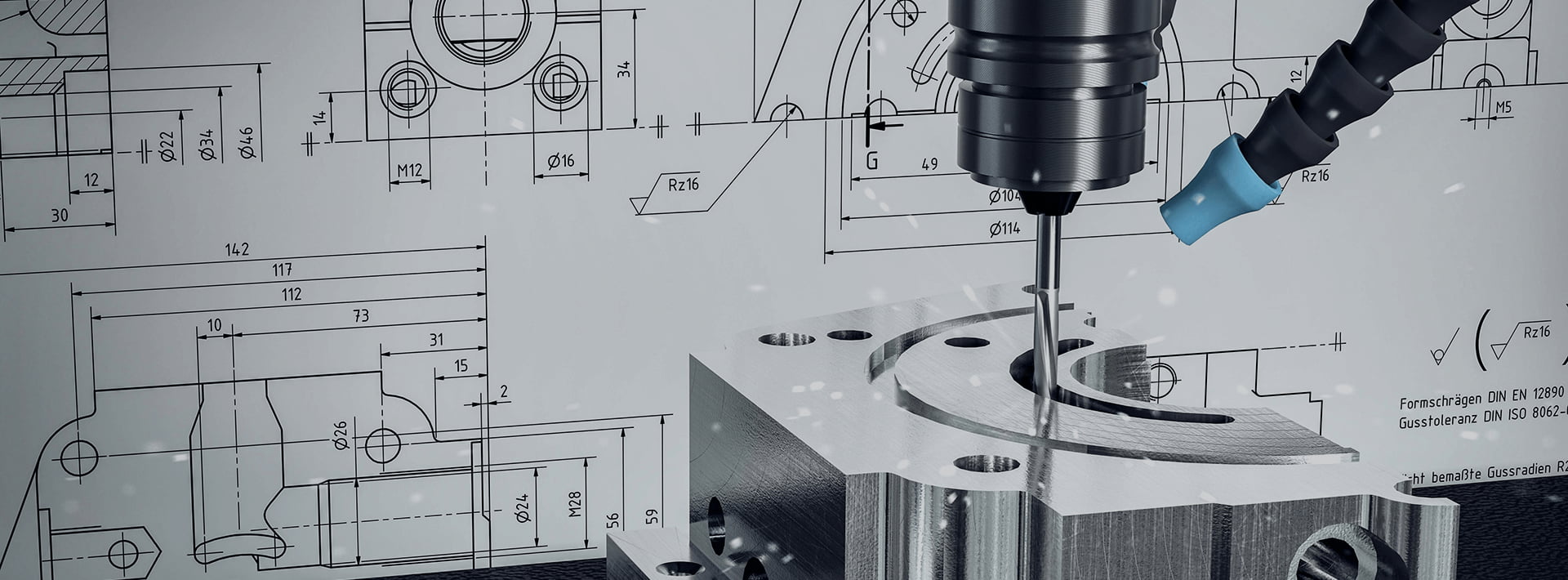

How to Improve CNC Machining Efficiency for Deep and Narrow Cavity Parts?

Improving CNC machining efficiency for deep and narrow cavity parts requires addressing challenges like tool rigidity, chip evacuation, heat buildup, and precision control. Here are key strategies:

. Optimize Tool Selection

- Use short, rigid tools: Choose carbide or high-speed steel (HSS) tools with shorter overhangs to reduce vibration and deflection, which are critical in deep cavities.

- Adopt specialized geometries: Tools with narrow diameters (matching cavity width) and spiral flutes (3-5 flutes) enhance chip evacuation. For very deep cavities, consider extended-length end mills with reinforced shanks.

- Coatings matter: Apply wear-resistant coatings (e.g., TiAlN, AlCrN) to tools to reduce friction and heat, extending tool life and allowing higher cutting speeds.

. Adjust Cutting Parameters

. Adjust Cutting Parameters

- Reduce cutting speed (VC) for deep cuts: High speeds in narrow spaces generate excessive heat; lower speeds (e.g., 100-300 m/min for carbide in steel) balance efficiency and tool longevity.

- Optimize feed rate (fz): Use moderate feed rates to ensure steady chip formation without overloading the tool. For example, 0.05-0.15 mm/tooth for steel.

- Control depth of cut (ap): Take multiple shallow passes instead of one deep pass to minimize tool stress and improve chip removal.

. Enhance Chip Evacuation

- Use high-pressure coolant: Direct pressurized coolant (100-1000 psi) into the cutting zone to flush chips out of the cavity. Through-spindle coolant systems are ideal for deep cavities.

- Air blasts or vacuum systems: For materials that are prone to chip welding (e.g., aluminum), combine coolant with air blasts or vacuum attachments to clear chips instantly.

- Program chip-breaking cycles: Incorporate pauses or retraction moves in the CNC program to allow chips to exit before resuming cutting.

. Improve Toolpath Strategies

- Climb milling over conventional milling: Climb milling reduces tool deflection by pushing the tool into the material, improving surface finish and reducing vibration in narrow spaces.

- Spiral or zigzag toolpaths: These distribute cutting forces evenly and avoid sudden direction changes, minimizing tool wear. For deep cavities, use layered (z-level) machining to clear material in steps.

- Roughing vs. finishing separation: First rough out the cavity with higher feeds/speeds to remove bulk material, then finish with slower, precise passes to ensure accuracy.

. Secure Workholding and Machine Setup

- Rigid fixturing: Use strong clamps or vacuum chucks to secure the workpiece, preventing movement during deep cuts that can cause inaccuracies or tool damage.

- Check machine rigidity: Ensure the CNC machine's spindle and axis drives are properly maintained (e.g., lubrication, backlash adjustment) to handle the stress of deep cavity machining.

. Leverage CNC Programming Techniques

- Use peck drilling/boring cycles: For deep cavities, program periodic retractions (pecking) to clear chips, especially in materials like cast iron or stainless steel that produce long chips.

- Simulate toolpaths: Use CAM software to simulate the machining process, identifying potential collisions, tool overhang issues, or inefficient paths before actual cutting.

By combining these strategies, you can reduce cycle times, minimize tool wear, and maintain precision-ultimately boosting efficiency for deep and narrow cavity parts.

. Optimize Tool Selection

- Use short, rigid tools: Choose carbide or high-speed steel (HSS) tools with shorter overhangs to reduce vibration and deflection, which are critical in deep cavities.

- Adopt specialized geometries: Tools with narrow diameters (matching cavity width) and spiral flutes (3-5 flutes) enhance chip evacuation. For very deep cavities, consider extended-length end mills with reinforced shanks.

- Coatings matter: Apply wear-resistant coatings (e.g., TiAlN, AlCrN) to tools to reduce friction and heat, extending tool life and allowing higher cutting speeds.

- Reduce cutting speed (VC) for deep cuts: High speeds in narrow spaces generate excessive heat; lower speeds (e.g., 100-300 m/min for carbide in steel) balance efficiency and tool longevity.

- Optimize feed rate (fz): Use moderate feed rates to ensure steady chip formation without overloading the tool. For example, 0.05-0.15 mm/tooth for steel.

- Control depth of cut (ap): Take multiple shallow passes instead of one deep pass to minimize tool stress and improve chip removal.

. Enhance Chip Evacuation

- Use high-pressure coolant: Direct pressurized coolant (100-1000 psi) into the cutting zone to flush chips out of the cavity. Through-spindle coolant systems are ideal for deep cavities.

- Air blasts or vacuum systems: For materials that are prone to chip welding (e.g., aluminum), combine coolant with air blasts or vacuum attachments to clear chips instantly.

- Program chip-breaking cycles: Incorporate pauses or retraction moves in the CNC program to allow chips to exit before resuming cutting.

. Improve Toolpath Strategies

- Climb milling over conventional milling: Climb milling reduces tool deflection by pushing the tool into the material, improving surface finish and reducing vibration in narrow spaces.

- Spiral or zigzag toolpaths: These distribute cutting forces evenly and avoid sudden direction changes, minimizing tool wear. For deep cavities, use layered (z-level) machining to clear material in steps.

- Roughing vs. finishing separation: First rough out the cavity with higher feeds/speeds to remove bulk material, then finish with slower, precise passes to ensure accuracy.

. Secure Workholding and Machine Setup

- Rigid fixturing: Use strong clamps or vacuum chucks to secure the workpiece, preventing movement during deep cuts that can cause inaccuracies or tool damage.

- Check machine rigidity: Ensure the CNC machine's spindle and axis drives are properly maintained (e.g., lubrication, backlash adjustment) to handle the stress of deep cavity machining.

. Leverage CNC Programming Techniques

- Use peck drilling/boring cycles: For deep cavities, program periodic retractions (pecking) to clear chips, especially in materials like cast iron or stainless steel that produce long chips.

- Simulate toolpaths: Use CAM software to simulate the machining process, identifying potential collisions, tool overhang issues, or inefficient paths before actual cutting.

By combining these strategies, you can reduce cycle times, minimize tool wear, and maintain precision-ultimately boosting efficiency for deep and narrow cavity parts.